Maintenance Guide: Strategies for Commercial Vehicle Lights

Maintaining commercial vehicle lights is a critical yet often underestimated aspect of fleet management. For fleet managers, vehicle technicians, and business owners, ensuring the proper functioning of vehicle lights can lead to enhanced safety, optimized performance, and compliance with legal requirements. A good maintenance routine is essential to the lifespan of any part of a vehicle, and that certainly includes the lights. From headlights to tail lights and beyond, every source of illumination requires upkeep.

This guide takes an in-depth look into developing effective maintenance strategies for commercial vehicle lights, including routine inspections and advanced upgrades, to equip you with the knowledge to keep your fleets running smoothly and safely. Maximize your maintenance routine now to ensure you never overlook a worn, broken, or otherwise ineffective bulb.

Consistent Light Maintenance Matters

Commercial vehicles operate under diverse and demanding conditions. Whether traveling through foggy routes, working overnight, or hauling freight over long distances, properly functioning lights play a key role in achieving peak illumination and visibility. Neglecting regular light maintenance may not only compromise the safety of drivers and the public but also increase the risk of costly downtime and non-compliance with vehicle regulations.

A proactive approach to monitoring and addressing lighting issues ensures optimal performance while extending the longevity of components. Browse high-quality commercial vehicle warning lights to easily obtain reliable hardware, but remember that great lights require proper handling and care. Relying on reputable suppliers and putting your lights in the hands of trusted experts ensures the best experience on the road, especially if you pair those factors with consistent upkeep.

The Different Types of Commercial Vehicle Lights

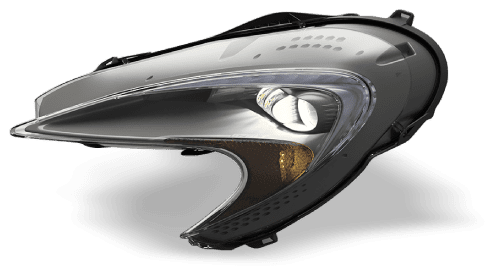

Understanding the variety of lights used in commercial vehicles is essential for designing a robust maintenance strategy. The primary categories include headlights for visibility during nighttime or poor weather, turn signals to indicate direction safely, brake lights to alert trailing vehicles, and marker lights to enhance the vehicle’s visibility on the road.

Each of these lights employs specific technologies, such as halogen, HID (high-intensity discharge), or LED. The LED vehicle lights are growing popular due to their energy efficiency, durability, and brighter output. Knowing the strengths and vulnerabilities of each technology helps target potential weak points for inspections and upgrades.

Inspecting Commercial Vehicle Lights Thoroughly

Inspection forms the backbone of light maintenance. Begin by reviewing the overall condition of each light.

Consider whether the lenses are clear and free of cracks. Cloudy, damaged, or fogged lenses can impair light intensity and compromise visibility, especially in adverse weather conditions. In addition, always keep an eye out for condensation inside the light housings. This step not only affects light performance but can also point to damaged seals that require immediate attention.

Next, evaluate the light beams. Make sure the headlights are properly aligned. Misaligned beams may reduce visibility and even irritate oncoming drivers. Activating each type of light—headlights, high beams, turn signals, brake lights, and tail lights—and walking around the vehicle to ensure all are functioning as expected should be part of every inspection.

Identifying and Addressing Common Lighting Problems

Several recurring issues can affect commercial vehicle lights. Reduced brightness can be the result of dust, dirt, or UV damage on lenses. Using cleaning products designed to restore clarity can address this drawback effectively. Flickering is another common problem that can stem from loose connections or faulty bulbs. A thorough inspection of electrical wiring and terminals can uncover and resolve such inconsistencies.

Burned-out bulbs are predictably one of the simplest issues to address but may indicate the need to switch to more durable and energy-efficient lighting such as LEDs. For vehicles experiencing complete light failure, the problem might extend to blown fuses or circuit issues, necessitating an electrical systems inspection.

Exploring the Advantages of LED Lights

LED upgrades also offer brighter light output than their predecessors, improving visibility for both the driver and nearby vehicles. However, understanding the considerations—such as compatibility with existing systems and the initial investment cost—is essential when planning for LED adoption.

Navigating Legal Regulations for Vehicle Lighting

Building maintenance strategies for commercial vehicle lights requires reflecting on any relevant road regulations. Compliance with transportation regulations is non-negotiable for fleet managers. Every commercial vehicle must, by law, adhere to specific standards for lighting, including required brightness levels, color, and positioning. Regulations can differ between states and countries, so consulting local guidelines ensures that your vehicles remain compliant.

Other legal elements include the use of reflective materials, such as marker tapes, to enhance visibility, especially for large-haul trucks. Failure to meet lighting requirements can result in costly fines, not to mention the safety risks such violations pose on the road.

Why Professional Maintenance Services Add Value

While routine inspections and repairs can be easily handled in-house, certain aspects of light maintenance benefit significantly from the expertise of professional technicians. Expert services often employ advanced diagnostic tools to detect subtle problems, such as irregularities in beam intensity or voltage inconsistencies, that might be missed during standard checks.

Professional maintenance can also streamline complex processes, such as retrofitting vehicles with LED systems or repairing extensive electrical damage caused by water ingress. Partnering with specialists ensures not only technical excellence but also peace of mind that your vehicles meet all operational and safety standards.

Practical Steps to Keep Your Lights Shining

Strategic light maintenance requires a balanced approach integrating routine checks, swift troubleshooting, and long-term improvements such as LED upgrades. By prioritizing safety, reliability, and compliance, fleet managers and vehicle technicians can cultivate confidence in their fleet’s performance, minimize downtime, and enhance driver safety.

For business owners managing multiple vehicles, outsourcing certain maintenance tasks or leveraging advanced diagnostics from professional providers can offer optimal efficiency while reducing effort. Whether inspecting components yourself or seeking external expertise, keeping your fleet’s lights functioning and bright remains a joint effort that drives overall success. Don’t wait until faulty lights jeopardize your fleet’s safety and efficiency—Implement these strategic maintenance practices today to ensure optimal vehicle performance and compliance.